A guide for buyers who want to ensure quality, efficiency, and sustainability in their supply chain with IATF 16949 accreditation

Introduction

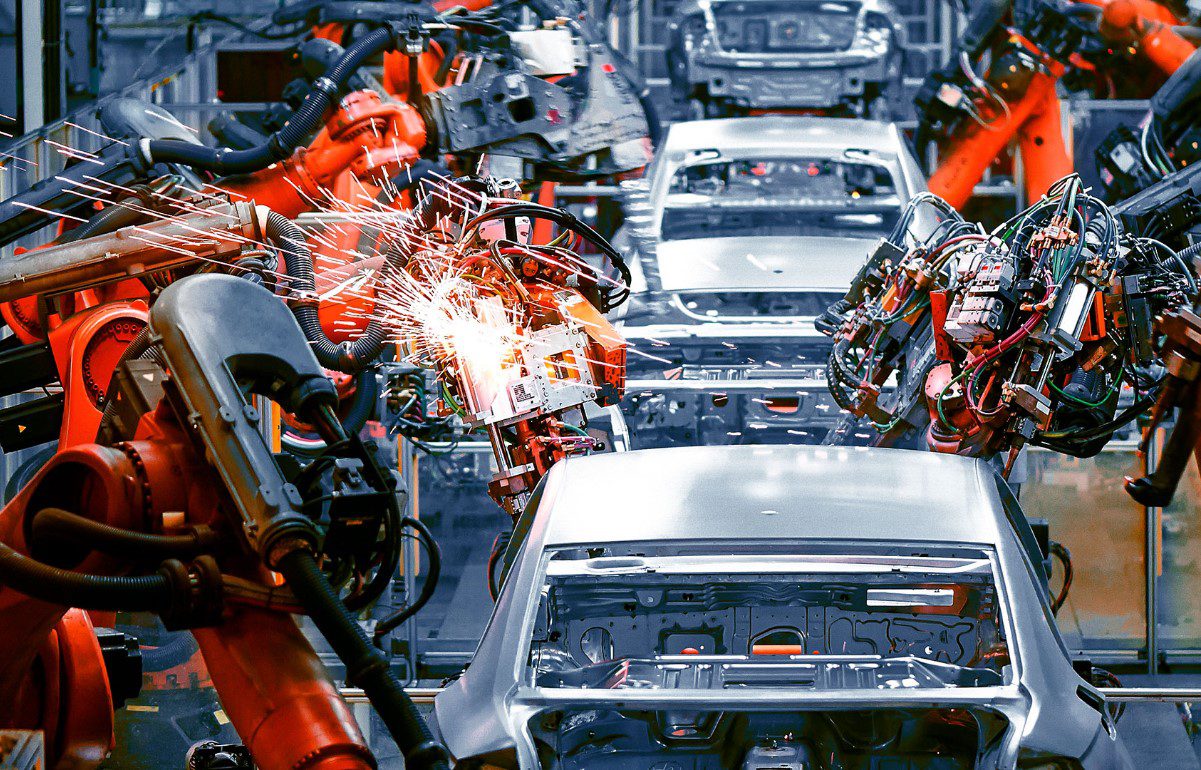

Manufacturing is a complex and competitive industry that requires constant innovation, adaptation, and improvement. To achieve these goals, manufacturers must rely on a network of suppliers who can provide them with the necessary materials, components, and services. However, not all suppliers are created equal. Some may have higher quality, efficiency, and sustainability standards than others. How can buyers distinguish between them and choose the best ones?

One way to do this is to look at the accreditation of the suppliers. Accreditation is verifying that a supplier meets certain requirements and follows specific guidelines recognised by the industry. It can also help buyers assess the suppliers’ capabilities, performance, and reliability, as well as their compliance with relevant regulations and standards. Accreditation can also help suppliers to demonstrate their commitment to excellence, continuous improvement, and customer satisfaction.

Suppliers can obtain different types of accreditation depending on their industry and scope of work. This blog post will focus on two of the most common and widely recognised ones for the automotive industry: ISO9001 and IATF 16949. We will explain what they are, how they differ, and why buyers should prefer suppliers with IATF 16949 accreditation over those with only ISO9001 accreditation. We will also provide real-world examples, innovative technologies, and insights from reputable sources supporting our argument. Finally, we will conclude by reflecting on why buyers should adopt these practices and a call for collective efforts to embrace them.

What are ISO9001 and IATF 16949?

ISO9001 is a general standard for quality management systems (QMS) that applies to any organisation, regardless of size, type, or industry. It specifies the requirements for establishing, implementing, maintaining, and improving a QMS that can help an organisation to meet its objectives and satisfy its customers. ISO9001 is based on the principle of continuous improvement and the Plan-Do-Check-Act cycle. It covers leadership, planning, support, operation, performance evaluation, and improvement. ISO9001 is the most widely used and recognised QMS standard globally, with over one million certificates issued in more than 170 countries.

IATF TS16949 is a specific standard for QMS that applies to the automotive industry. It is based on ISO9001 but adds additional requirements and guidelines specific to the automotive sector. It was developed by the International Automotive Task Force (IATF), a group of leading automotive manufacturers and trade associations, to harmonise the global automotive market’s different QMS standards and expectations. IATF 16949 covers customer-specific requirements, product design and development, risk management, change management, supplier management, product traceability, product safety, and warranty management. IATF 16949 is the most widely used and recognised QMS standard in the automotive industry, with over 80,000 certificates issued in over 80 countries.

Benefits of IATF 16949 accreditation?

While ISO9001 accreditation is a valuable and necessary asset for any supplier, it is not enough to ensure the highest quality, efficiency, and sustainability in the automotive industry. The automotive industry is one of the world’s most demanding and dynamic industries, with high expectations from customers, regulators, and stakeholders. It faces challenges such as increasing competition, changing customer preferences, environmental and social issues, technological disruptions, and global supply chain risks. To cope with these challenges, the automotive industry needs suppliers who can not only meet the general requirements of ISO9001, but also the specific requirements of IATF 16949.

Therefore, buyers who want to ensure quality, efficiency, and sustainability in their supply chain should prefer suppliers with IATF 16949 accreditation over those with only ISO9001 accreditation. Here are some of the benefits of doing so:

- Improved quality and customer satisfaction: IATF 16949 accreditation helps suppliers deliver products and services that meet or exceed customers’ expectations and regulatory and statutory requirements. It also helps suppliers prevent defects, reduce waste, and improve customer feedback and complaint handling, which can result in improved quality and customer satisfaction, as well as reduced costs and risks.

- Enhanced efficiency and productivity: IATF 16949 accreditation helps suppliers optimise their processes, resources, and performance by applying the best practices and tools of the automotive industry. It also helps suppliers identify and eliminate the root causes of problems and implement corrective and preventive actions. This can result in enhanced efficiency and productivity, as well as increased profitability and competitiveness.

- Increased sustainability and innovation: IATF 16949 accreditation helps suppliers incorporate sustainability and innovation into their QMS by addressing the environmental and social impacts of their activities and fostering a culture of continuous improvement and learning. It also helps suppliers to adopt and integrate new technologies, methods, and solutions that can improve their products and services, and create value for their customers and stakeholders. This can result in increased sustainability and innovation, as well as improved reputation and market share.

Real-world examples

To illustrate the benefits of IATF 16949 accreditation, we will provide real-world examples, innovative technologies, and insights from reputable sources that support our argument. These are not exhaustive, but they indicate the trends and opportunities in the automotive industry.

- Real-world example: Bosch, a leading global supplier of technology and services for the automotive industry, has been certified to IATF 16949 since 2016. According to its website, Bosch uses IATF 16949 as a framework to ensure quality, efficiency, and sustainability in its operations, products, and services. Bosch claims that IATF 16949 helps it to achieve customer satisfaction, operational excellence, and innovation leadership, as well as to comply with the highest standards of environmental and social responsibility. Bosch also states that IATF 16949 enables it to collaborate effectively with its customers and suppliers, and to adapt to the changing needs and expectations of the automotive market.

- Innovative technology: Blockchain, a distributed ledger technology that enables secure and transparent transactions, is emerging as a potential solution for improving the quality, efficiency, and sustainability of the automotive supply chain. According to a report by IBM, blockchain can help the automotive industry achieve the following benefits:

- Enhance product traceability and provenance by creating a digital record of the origin, ownership, and movement of the products and materials throughout the supply chain.

- Enabling the sharing of information, documents, and contracts among the parties involved in the supply chain and facilitating the verification and validation of the suppliers’ credentials and performance will improve supplier management and collaboration.

- Enabling the detection and prevention of counterfeit, defective, or non-compliant products and materials and facilitating the recall and remediation of the affected products and customers will increase product safety and compliance.

- Eliminating intermediaries, inefficiencies, and errors in the supply chain and enhancing the security and resilience of transactions and data will reduce costs and risks.

- Enabling the development of new products, services, and business models that leverage the data and insights generated by the blockchain network will drive innovation and value creation.

Insight from a reputable source: The Automotive Industry Action Group (AIAG), a not-for-profit association of automotive manufacturers, suppliers, and service providers, is one of the founding members of the IATF and a leading advocate of IATF 16949. According to its website, AIAG provides training, certification, and resources to help the automotive industry implement and maintain IATF 16949. AIAG also publishes standards, guidelines, and best practices that complement and support IATF 16949, such as the Core Tools (APQP, FMEA, MSA, SPC, PPAP), the Automotive Warranty Management Guideline, and the Corporate Responsibility Guideline. AIAG states that IATF 16949 is a key enabler of quality, efficiency, and sustainability in the automotive industry, and that it is essential for the automotive industry to adopt and embrace it.

Conclusion

In conclusion, we have explained what ISO9001 and IATF 16949 are, how they differ, and why buyers should prefer suppliers with IATF 16949 accreditation over those with only ISO9001 accreditation. Pressmark has also provided real-world examples, innovative technologies, and insights from reputable sources supporting our argument. We hope this blog post has helped you understand the significance and benefits of using IATF 16949-accredited suppliers instead of ISO9001-accredited suppliers. Pressmark believes this is not only a matter of preference, but also a matter of necessity, for the automotive industry. We urge you to adopt these practices and to join us in our collective efforts to embrace them.