T he automotive industry faces unprecedented challenges in its supply chain management. This is due to factors such as raw material shortages, transportation disruptions, energy price hikes, currency fluctuations and pandemic lockdowns. These challenges have exposed the vulnerabilities of the current supply chain model. The existing supply chain relies heavily on just-in-time inventory practices and global sourcing of critical components such as semiconductors.

Read morePressmark utilise sensors to collect data and improve business processes

T he Manufacturing Information Platform (MIP) created by WMG, part of the University of Warwick, has been helping Pressmark collect data to improve its manufacturing processes. So far, the technology has helped the business analyse machine downtime, discover the bottleneck and change the process to become more time-efficient.

Atherstone based high-quality metal pressings firm Pressmark has been continuously improving business throughout their longevity, regardless of challenges brought on by the pandemic. With the knowledge and capability of supporting a wide variety of clients, the firm strives to improve its customers’ experience through collecting data and reducing downtime where possible.

Read moreHow Industry 4.0 will reinvigorate UK manufacturing

I n manufacturing technology, there is a current trend in data exchange and automation called Industry 4.0 (pronounced four point zero). It mainly comprises the internet of things, cognitive computing, cyber-physical systems, and cloud computing. Industry 4.0 is also called the fourth industrial revolution. Industry 4.0 is about digitisation that brings the physical and virtual worlds closer together. This ensures that each learns from one another. Although Industry 4.0 has set out to transform how companies approach business, the UK is lagging in this. As a result, it has a hurdle to climb to keep up with other European countries and other international countries.

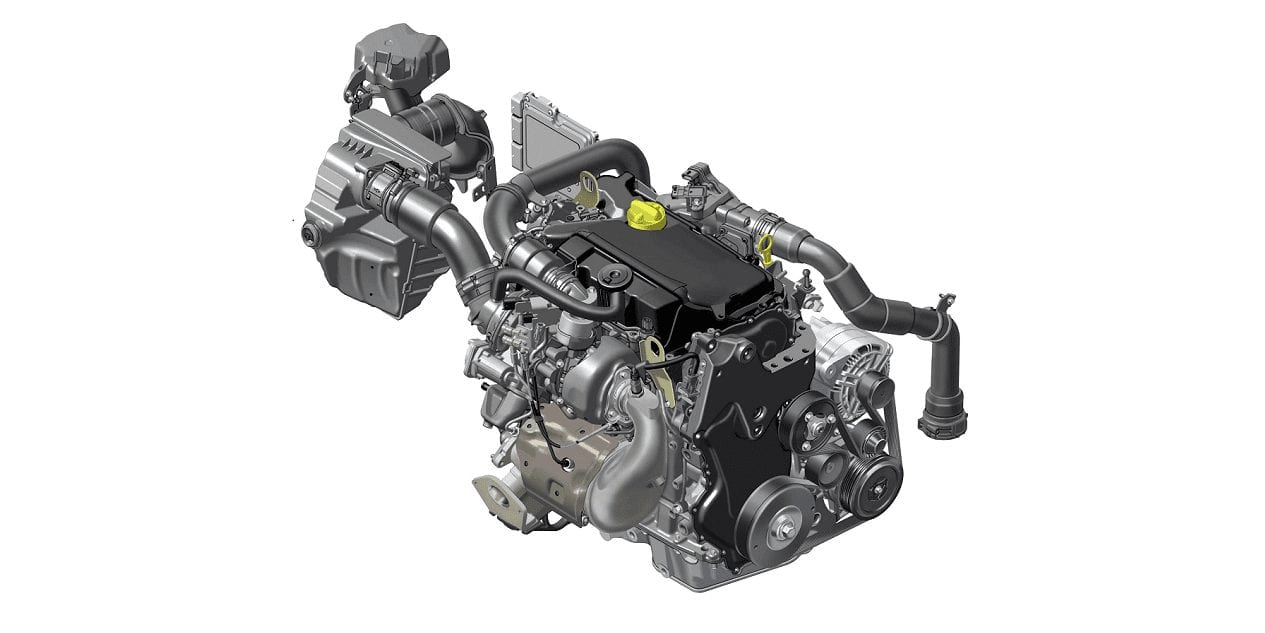

Diesel engine – is it dying or not? Have your say!

N ow the question is, is there any way back for the diesel engine in the UK market? To get the right answer to this question we need to consider a lot of things, according to a European commissioner that said, ‘Diesel cars are finished’. Not everybody will accept his claim, but let’s review a few things and then consider if there is any future hope for the diesel engine in the UK market.

Midlands based Pressmark joins leading industry network

Pressmark Pressings has joined the leading Midlands manufacturing and engineering membership group Made in the Midlands (MIM).

Pressmark celebrates MBI anniversary with £2m sales boost

A Warwickshire-based metal forming specialist is celebrating a major transformation in fortunes just one year after a Management Buy-In (MBI) was completed with a sales boost.

FMEA & FEA – impact on Aerospace & Defence Manufacturing

Aerospace & defence manufacturing usually commands a lot of expertise, as both industries deal with production of systems with both complex designs and functionality. Therefore, their entire manufacturing processes are carried out with an extra level of precision, since any small defect will inevitably lead to the loss of multiple lives.

For instance, whenever aircraft are in the air, the lives of those in it are solely dependent on how well the systems of the aircraft were designed, developed and manufactured. Any minor errors that are made during the design, development or manufacture of any one of the thousands of components in the aircraft, will potentially lead to a significant number of fatalities. The same applies to any of the defence vehicles which are used by our military personnel, where the lives of the men and women in uniform using them, are dependent on how well these machines were designed, assembled and tested.

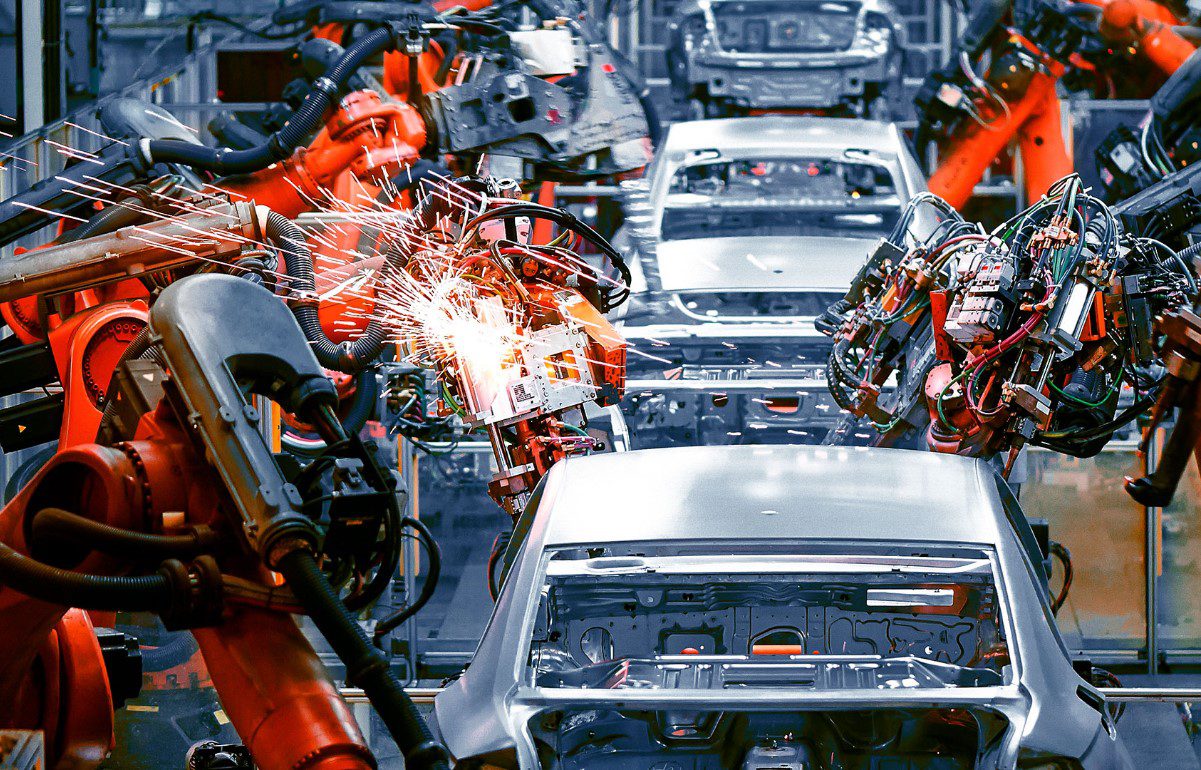

Chassis Manufacturing Process

A vehicle frame forms the basis of an automobile which, known as the chassis, this frame supports the sub-assemblies and other components of the car. The chassis also provides stability to the car from the variety of forces and impacts that it has to sustain throughout its life. The construction of the frame is of a uni-body type in the case of passenger cars and most commercial vehicles, such as trucks, are produced with a body-on-frame construction.

Choosing sustainable products and materials

The increasing availability of product environmental information provides an opportunity for consumers to choose more sustainable products and for designers to be rewarded for selecting more sustainable materials. Here are some tips on how to do this.

Euro 6 standards are changing the automotive industry

In an effort to reduce CO2 emissions throughout the whole of Europe, it is now mandatory for all new cars sold within the EU to meet Euro 6 standards for exhaust emissions, no matter where they are manufactured. NOx and other pollutants are monitored and recorded from every manufactured vehicle.