T he automotive industry faces unprecedented challenges in its supply chain management. This is due to factors such as raw material shortages, transportation disruptions, energy price hikes, currency fluctuations and pandemic lockdowns. These challenges have exposed the vulnerabilities of the current supply chain model. The existing supply chain relies heavily on just-in-time inventory practices and global sourcing of critical components such as semiconductors.

Read moreFMEA & FEA – impact on Aerospace & Defence Manufacturing

Aerospace & defence manufacturing usually commands a lot of expertise, as both industries deal with production of systems with both complex designs and functionality. Therefore, their entire manufacturing processes are carried out with an extra level of precision, since any small defect will inevitably lead to the loss of multiple lives.

For instance, whenever aircraft are in the air, the lives of those in it are solely dependent on how well the systems of the aircraft were designed, developed and manufactured. Any minor errors that are made during the design, development or manufacture of any one of the thousands of components in the aircraft, will potentially lead to a significant number of fatalities. The same applies to any of the defence vehicles which are used by our military personnel, where the lives of the men and women in uniform using them, are dependent on how well these machines were designed, assembled and tested.

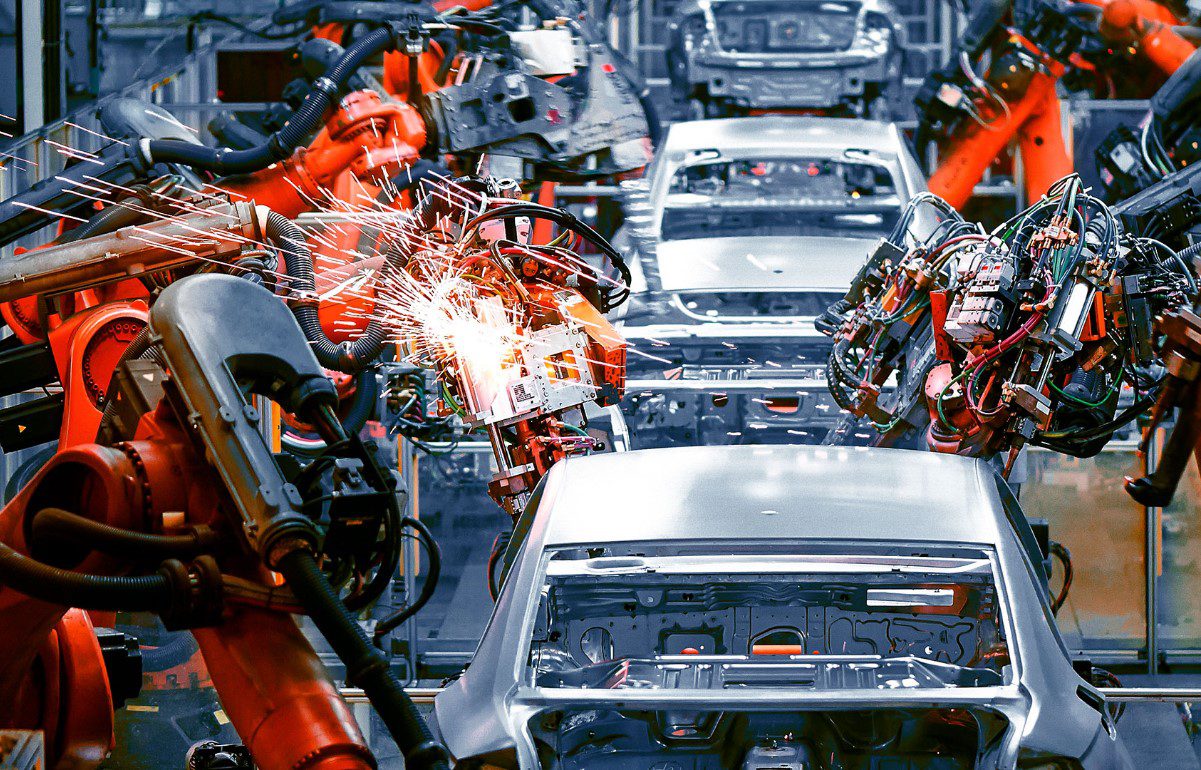

Chassis Manufacturing Process

A vehicle frame forms the basis of an automobile which, known as the chassis, this frame supports the sub-assemblies and other components of the car. The chassis also provides stability to the car from the variety of forces and impacts that it has to sustain throughout its life. The construction of the frame is of a uni-body type in the case of passenger cars and most commercial vehicles, such as trucks, are produced with a body-on-frame construction.

Multitasking materials in construction & architecture

Installations of materials are often a practically invisible part of a building. Miles of cables, piping, tubes and wires are concealed behind the ceilings, floors, walls and foundations. The facilities themselves are tucked behind voids or form unsightly blemishes on rooftops.

Design & Advanced Material-Driver of Innovation

In recent years, advanced materials have emerged and significantly impacted the products around us and their design. Coming from science and technology, advanced materials can outperform traditional materials as they can be tougher, withstand higher temperatures, and be tailored into new shapes.